Leading supplier of fr fabric offering custom designs and certified protection for global safety standards

Safety and performance have become inseparable in modern industrial environments, and the quality of protective clothing directly impacts worker well-being. As the demand for specialized protective textiles continues to grow worldwide, manufacturers are striving to deliver fabrics that combine durability, flexibility, and compliance with international safety standards. Among them, LEVITEX® has emerged as a global leader, producing exceptional fr fabric that meets the most stringent industrial requirements while offering customization options for every client’s specific needs.

Safety and performance have become inseparable in modern industrial environments, and the quality of protective clothing directly impacts worker well-being. As the demand for specialized protective textiles continues to grow worldwide, manufacturers are striving to deliver fabrics that combine durability, flexibility, and compliance with international safety standards. Among them, LEVITEX® has emerged as a global leader, producing exceptional fr fabric that meets the most stringent industrial requirements while offering customization options for every client’s specific needs.

The Science Behind Flame Resistant Fabric

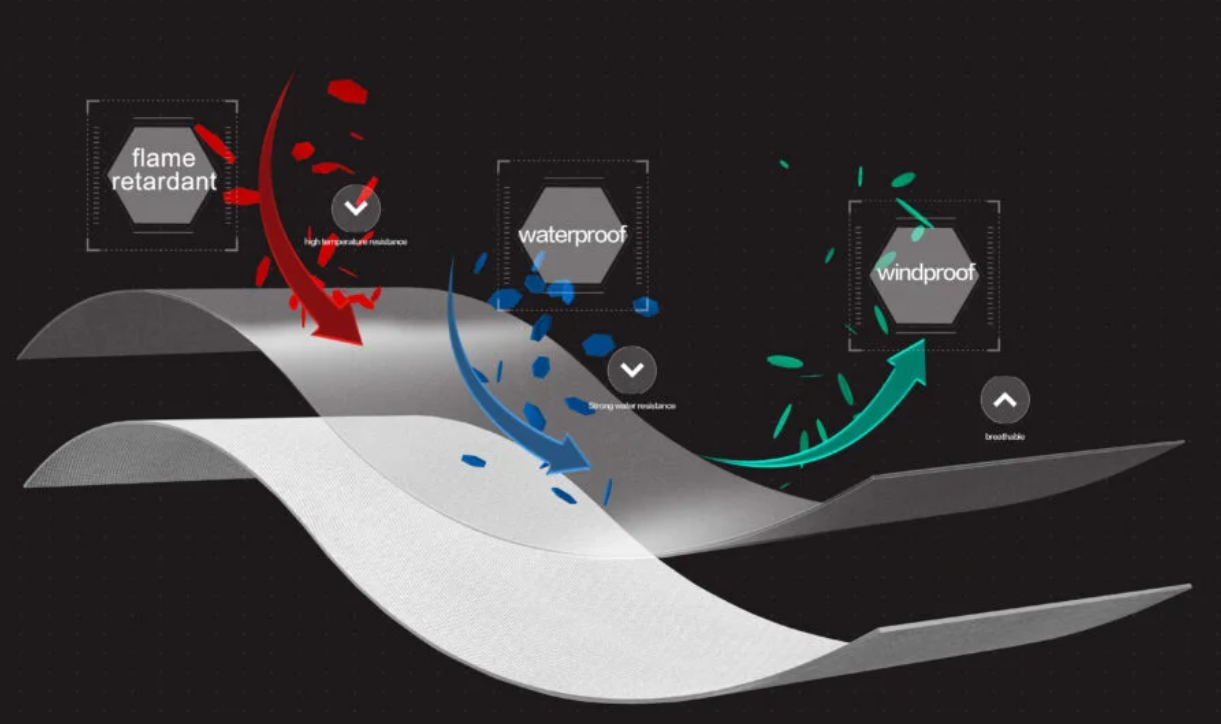

Flame resistant fabric is not simply another textile—it is an engineered safety material designed to reduce fire-related injuries and save lives. Its primary function is to resist ignition and self-extinguish when exposed to flames. LEVITEX® utilizes a proprietary after-treatment process that embeds fire-retardant properties deep within the fabric fibers, ensuring long-term stability and wash durability.

This scientific process transforms natural and blended fibers into high-performance fr fabric capable of withstanding high temperatures without melting or dripping. The result is a material that provides superior protection while maintaining softness and breathability, ideal for workwear and uniforms across industries.

A Legacy of Manufacturing Excellence

LEVITEX® has cemented its position as one of the largest and most respected flame retardant fabric producers in China. With over 37.2% of the country’s cotton FR fabric production, the company has become synonymous with reliability and innovation. Its large-scale manufacturing facilities employ cutting-edge weaving, dyeing, and finishing technologies that ensure precision and quality control at every stage.

This robust infrastructure allows LEVITEX® to meet both bulk and custom orders efficiently, catering to clients ranging from local safety equipment manufacturers to global apparel brands. Each product reflects the brand’s unwavering commitment to safety, comfort, and visual excellence.

Customization for Industry-Specific Needs

One of the defining features of LEVITEX®’s success is its ability to offer customized fr fabric solutions. Recognizing that different sectors face unique risks, the company designs fabrics that align with specific operational environments. For instance, oil and gas companies require heavier, heat-resistant textiles, while electrical workers prefer lightweight fabrics that provide mobility and arc protection.

Clients can also request variations in color, weave structure, and coating thickness, ensuring the final product aligns perfectly with their branding and safety requirements. This versatility has made LEVITEX® a preferred partner for international companies seeking consistent quality and design flexibility.

Commitment to Global Safety Standards

LEVITEX® operates under strict quality assurance systems that align with leading international safety regulations. Its flame resistant fabric meets certifications such as ISO 11612, EN ISO 14116, and NFPA 70E, verifying its performance under real-world conditions. The company’s internal laboratory conducts extensive testing for flame spread, thermal resistance, and mechanical strength to guarantee consistent protection.

These certifications not only demonstrate product reliability but also build global confidence in LEVITEX® as a trusted textile supplier. Whether the end-use application is industrial coveralls, firefighting gear, or arc flash uniforms, the company ensures every fabric upholds the highest level of safety.

Innovation and Technology at the Core

LEVITEX® continuously invests in research and development to refine its textile technology. The company’s scientists and engineers collaborate to develop new fabric blends that improve durability, comfort, and resistance to external stress. By integrating nanotechnology and advanced finishing methods, LEVITEX® has enhanced the overall performance of its fr fabric—making it lighter, stronger, and longer-lasting.

These innovations allow the brand to stay ahead in a highly competitive market and respond effectively to the evolving demands of modern industries. LEVITEX®’s proactive approach to product development has solidified its position as a leading name in flame resistant fabric manufacturing.

Sustainable Practices and Environmental Responsibility

LEVITEX® understands that sustainability is not just a trend but a long-term commitment. Its production facilities adhere to eco-friendly standards, using water-efficient dyeing systems and non-toxic finishing agents. The company’s continuous investment in clean technology demonstrates a dedication to minimizing environmental impact while maintaining superior fabric performance.

Furthermore, LEVITEX® supports sustainable sourcing by working closely with responsible cotton suppliers. By balancing safety innovation with environmental stewardship, the company ensures that its flame resistant fabric production contributes positively to both industry and ecology.

Building Global Partnerships through Trust

As a global supplier, LEVITEX® serves an extensive network of clients in Europe, North America, the Middle East, and Southeast Asia. Its reputation for consistency and customer satisfaction has made it a reliable partner for organizations that value safety, quality, and long-term collaboration. The company’s transparent communication, strict quality control, and flexible logistics solutions make international procurement smooth and dependable.

LEVITEX®’s success story is built on trust, innovation, and a relentless pursuit of excellence. Every piece of fr fabric that leaves its production floor reflects these values—representing not just a product, but a promise of safety and performance.

To discover more about their wide range of flame resistant fabric solutions and customization services, visit https://frfabric.com/ and explore how LEVITEX® continues to shape the global standard for protective textile innovation.